Anglian Water, one of the UK’s largest water and wastewater treatment companies (operating over 1,000 wastewater treatment works in the East of England), has chosen Atlas Copco’s low pressure ZS blowers to supply air to the aeration diffusers at four of its wastewater treatment re-development sites.

Anglian Water, one of the UK’s largest water and wastewater treatment companies (operating over 1,000 wastewater treatment works in the East of England), has chosen Atlas Copco’s low pressure ZS blowers to supply air to the aeration diffusers at four of its wastewater treatment re-development sites.

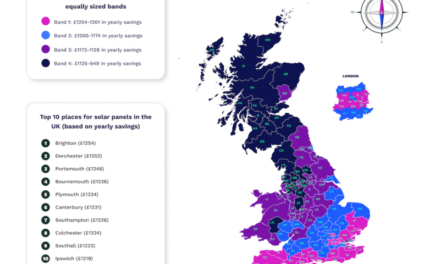

A total of 22 Atlas Copco ZS90 rotary screw blowers will be installed at the sites in Colchester, Letchworth, Bedford and Flag Fen, near Peterborough as part of Anglian Water’s initiative to find innovative ways of reducing its energy costs.

Wastewater treatment plants use bacteria to break-up waste which requires large quantities of air to be blown into aeration tanks. In a typical biological wastewater treatment plant, the blower system will account for up to 70% of energy usage.

Anglian Water approached Hydrok, an aeration diffuser and IFAS specialist, about supplying submerged, high efficiency, bubble aeration framework systems incorporating bio-textile curtains and fixed bed media. These units improve the distribution of aeration air to maintain the desired level of dissolved oxygen within the wastewater containment system.

Hydrok matched their high efficiency diffuser technology with Atlas Copco ZS low pressure screw blowers, which make energy cost savings of up to 35% possible, for optimum performance. The ZS90 range of variable speed drive, oil-free rotary screw displacement blowers comprise a complete, fully integrated package based on a simple internal principle – precision timing gears maintain minute clearances between two intermeshing oil-free screw elements that never touch.

No lubrication is required in the compression space and special seals stop any rotor bearing oil from entering the compression chamber. Intake air is compressed between the rotors and their housing and oil-free, pulsation-free air at pressures of 550-700mbar is delivered at an output rate of between 1,300-4,500Nm3/h-free air delivered dependent upon process demand.

Atlas Copco ZS blowers fitted with weather-proofing kits for external installation are being installed at Anglian Water’s wastewater plants in Flag Fen and Bedford. Using the ZS range will also allow Anglian Water to locate the blower motor inverters, controls and condition monitoring in an Anglian Water designed purpose built MCC room. At the Letchworth and Colchester sites, the blowers will be located within an existing plant room.

In the case of the Letchworth site Anglian Water also chose to reduce installation costs by installing ZS+ blowers. ZS+ blowers are supplied with an integrated frequency converter which varies the speed of the 90kW motor to match changes in the blower air demand, thus consuming only the minimum amount of energy. As an additional benefit, the ZS+ range of blowers are fitted with the Atlas Copco Elektronikon operating system to provide control, to monitor the overall system performance status, and to increase the blowers’ efficiency and reliability.

Hydrok product manager, Mark Lunn, explained why Atlas Copco ZS blowers were chosen to meet Anglian Water’s performance and energy saving criteria, “These proven units will deliver a reliable supply of totally oil-free air, which is an important factor in our specifications, and we are confident that there will be a very positive contribution to improving energy efficiency and reducing Anglian Water’s carbon footprint. As a contractor, we also benefit from Atlas Copco being a supplier partner that can provide us with complete 24/7 product support.”